Togolese geographer, Kodjo Afate Gnikou, invented an entirely recycled 3D printer using discarded mainframes, second-hand scanners, and tinkering. He built a 3D printer using only electronic waste that he salvaged from landfill sites.

Gnikou wants to use his printer to improve the lives of his countrymen by “printing” objects such as medical prostheses. Recycling these materials, he said, also helps fight against the worsening electronic waste problem in Togo.

Gnikou first saw a “Mendel” – an artisanal self-replicating 3D printer in August 2012 during a workshop in Lomé. “At first, the machine fascinated me due to all the creative possibilities it offered. But I very quickly realized that this type of machine was not accessible to everyone, because they are built from printed pieces that were also made by 3D printers! Often, they need to be ordered and imported from Europe, which ends up being very expensive,” he said.

“Many second-hand computers are shipped from Europe to Ghana and Nigeria. These machines are dumped in large landfill sites that are very poorly regulated. It’s hard to say how many tonnes of electronic waste can be found in these sites, but it’s clear that more and more waste is building up as the years goes by,” Gnikou added.

In a bid to find a solution to the waste problem he had identified, Gnikou challenged himself to make a 3D printer entirely out of electronic waste found in these landfill sites.

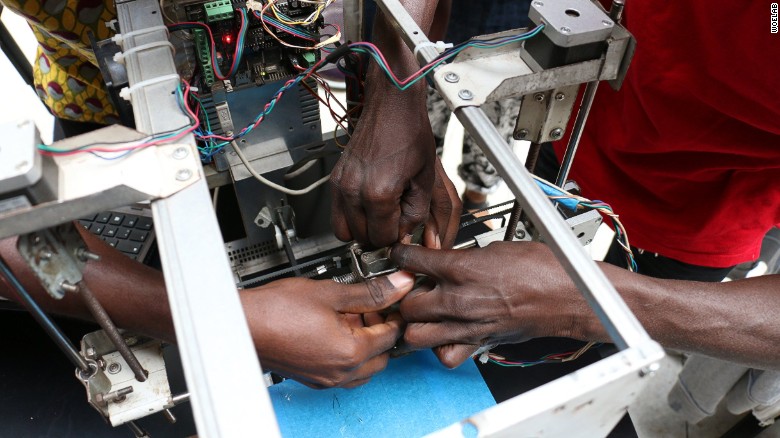

Gnikou went hunting for old mainframes, discarded scanners, connection bars, and components in the landfills of Lomé. “I basically took anything that could potentially be used to create the chassis and the electronic part of the printer”.

He said it took him six months to develop the first prototype. “I received support from an incubator, WoeLab that is located in Djidjolé, a lower-income neighbourhood in Lomé. They got unemployed youths to come see me work and to get involved in the project”.

“Many people told us that what we’re doing is very complicated, that it’s reserved for ‘the elite’. I have no background in computer science; my studies were in literature. Building a model like this is a question of will and creativity”.

“The first object that we printed was one that I had designed from A to Z on 3D modelling software: A pen holder. On it, we had written “right to dream”, our motto from the beginning,” he said.

They’ve created the first made in Africa 3D printer using e-waste. The machine can print plastic objects that range from a few centimetres to a metre in length. They sold their first printer during an innovation fair in Abidjan.

According to the trained geographer, he aims to create a series of such machines, launch training workshops and partner with Internet cafés in order to make their use more democratic.

“Once you have the machine and know how to use it, all you need to do is download models online, and after that, creating objects is as easy as opening a PDF file!” he noted.

In 2014, Gnikou won a prize at FAB10 Barcelona, a meeting of international tech entrepreneurs and inventors. He has been working conscientiously on a more powerful model. “The first model was hard to transport because it was quite fragile. The new model is much more solid,” he stated.

Gnikou is already fulfilling his dream of using his printer to make medical prostheses. He has already created knee prostheses built to fit individual patients. They were created with the first Togolese 3D printer created by the WoeLab.

As at 2016, Gnikou estimated that he had used his 3D printers to create about 150 objects. The largest object he printed was a cup that was 16 cm wide and 12 cm tall.

He is keen on training young people to build machines themselves. “My goal would be to get them to the point where they are able to create objects that respond to concrete needs or help them in their daily lives”.